Dosing and mixing plant

New dosing and mixing plant installed at VAUTID factory in Wendlingen

June 2019 saw the start of installation and commissioning of a new dosing and mixing plant at the VAUTID factory in Wendlingen. The formulations of individual VAUTID products are currently being entered into the plant´s control system. Trial runs are being undertaken to ensure optimal results, where mix ratios perfectly match material recipes.

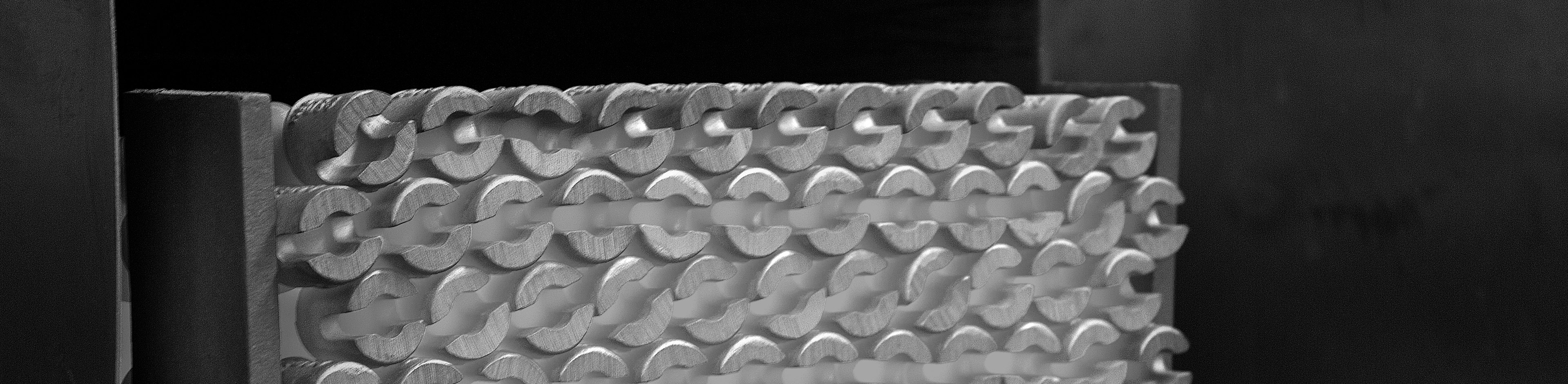

The new high-speed plant has a capacity of over 6,000 metric tons per year. Operating as a closed system, a computer-controlled process doses raw materials in gram-accurate amounts for mechanically bonding with base materials to achieve a fully homogenous hardfacing material or material concentrate. The resulting VAUTID ADD material is a perfect example of the consitent high quality of VAUTID products.

The new plant includes a recirculating vacuum air filtration system with a hot air return facility. This increases our contribution to environmental protection and improves process reliability at the same time. And it guarantees the continuing high quality of the hard-facing materials and wear plates offered by VAUTID GROUP throughout our global operations.

It ensures a consistency in product quality not only in our factories in Germany, but also at our subsidiary companies abroad. These also benefit from new technology, and they offer a uniform standard of quality which matches that of our German sites.

This investment in plant capacity and technology demonstrates VAUTID´s commitment to our production sites in Germany – not just for now, but for the future as well.